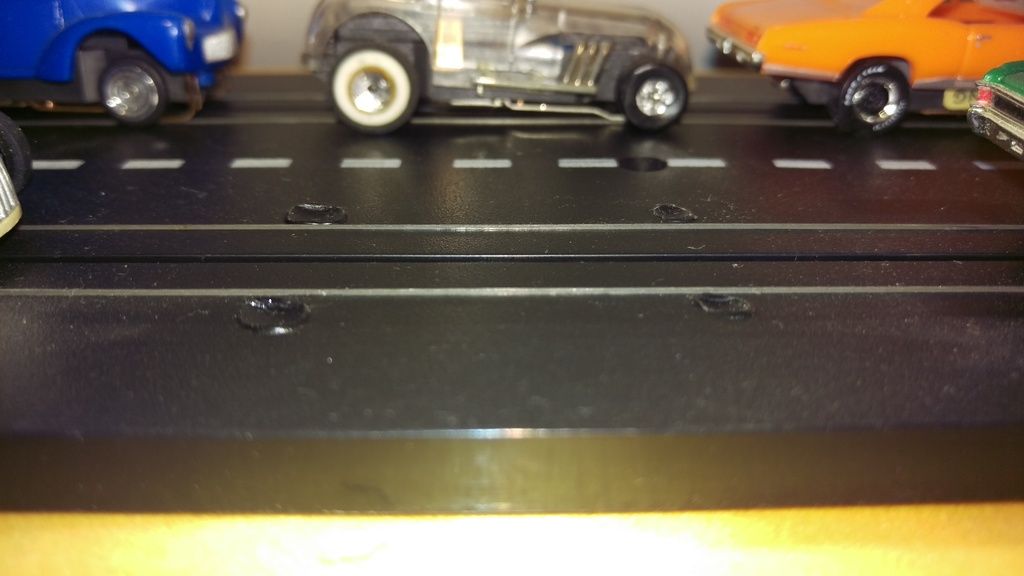

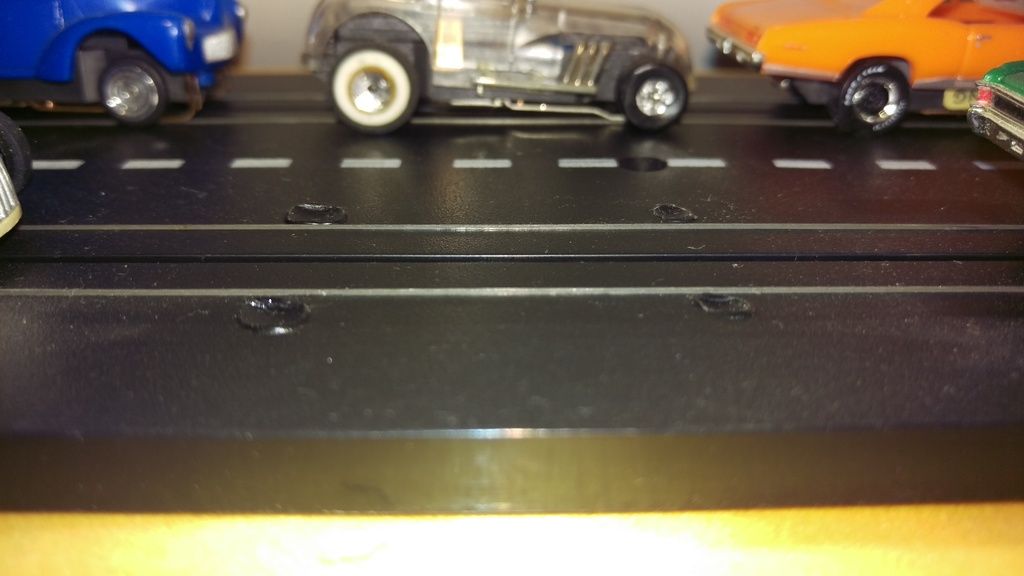

These are the older rims and tires .Never seen it before .I do remember seeing people posting this but it's a first for me.

I remember the issue also came up later in regard to the tires on the slot car chassis that Tyco/Mattel was clearancing out online for $3.00 each.I first brought this up back in 2007...

http://www.hobbytalk.com/bbs1/showthread.php?t=192012&highlight=melt+track

Not quite the same problem, but related. I've been wondering how the JL pullback wheels would work on powered cars. Apparently not so well with the tires that came on them. Too bad. The wheels look so great.I have swapped out the JL tjet wheels for the JL pullback wheels and found that the pullback tyres, when exposed to oil will begin to melt and make a sticky mess! The pullback tyres are a plastic/vinyl, me thinks.